What is the use of graphite? What is the grinding process?

What is the use of graphite? What is the grinding process?

Blog Article

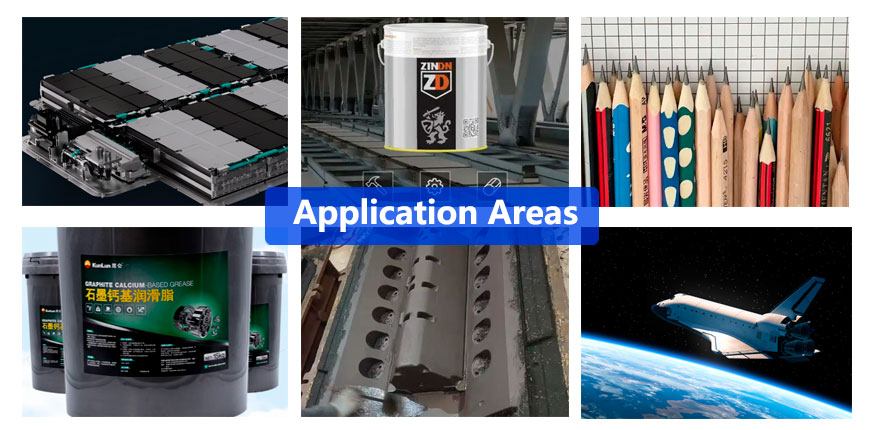

Graphite is a very common natural organic mineral, mainly composed of carbon elements stacked in a single-layer flake structure. Graphite not only has a waxy texture and metallic luster, but also has relatively low hardness. It also has the characteristics of thermal conductivity, electrical conductivity, lubricity, high temperature resistance and chemical stability. It is widely used in the following industries:

What is the use of graphite?

1. Battery field

As a highly conductive material, graphite has good electrical conductivity and chemical stability. It can be used for a long time and withstand large currents. It is widely used in the negative electrode materials of batteries, such as alkaline batteries, lead-acid batteries, lithium-ion batteries, etc.

2. Coating field

Because graphite has high temperature stability and corrosion resistance, it can protect the coating surface and can be made into black pigments. It is widely used in coatings, high-temperature paints, ship paints and other fields.

3. Pencil lead field

Graphite has low hardness, is brittle and soft, can leave obvious marks on paper, and can be used as the main material of pencil leads.

4. Lubrication field

The layered structure of graphite gives it good lubricity and can be used to make lubricating oils, high-temperature greases and other lubricants. It is widely used in the manufacture of high-speed mechanical lubricants such as trains, ships, and airplanes.

5. Casting field

Graphite has high chemical inertness and low thermal shrinkage and can be used to make cast iron. High-strength cast iron and thin-walled cast parts usually use graphite materials, which are mainly used to manufacture aerospace equipment and automobile engine parts.

6. Aerospace field

Graphite has the characteristics of high strength, high temperature resistance and light weight. Graphite composite materials are widely used in the manufacture of rockets and aircraft to improve the strength of the mechanism and reduce weight. It can also be used to manufacture pneumatic cushions to improve the lift effect of the aircraft.

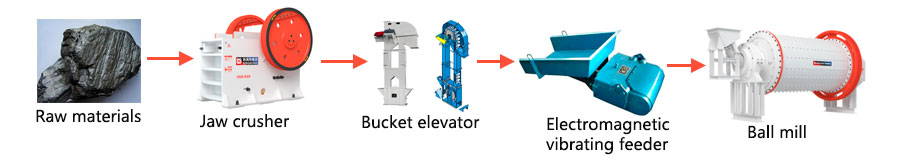

What is the grinding process?

It is composed of jaw crusher, ball mill, reducer, analyzer, pipeline device, blower, dust collector, bucket elevator, electromagnetic vibrating feeder, electronic control system, etc. The grinding system has high output and low energy consumption, high product fineness, clean, environmentally friendly, safe and reliable.

Advantages of ball mill

Ball mill can grind natural graphite efficiently. It is a kind of equipment that achieves crushing effect by rolling and crushing materials. The crushing method adopted is relatively gentle and can better protect the integrity of graphite particles.

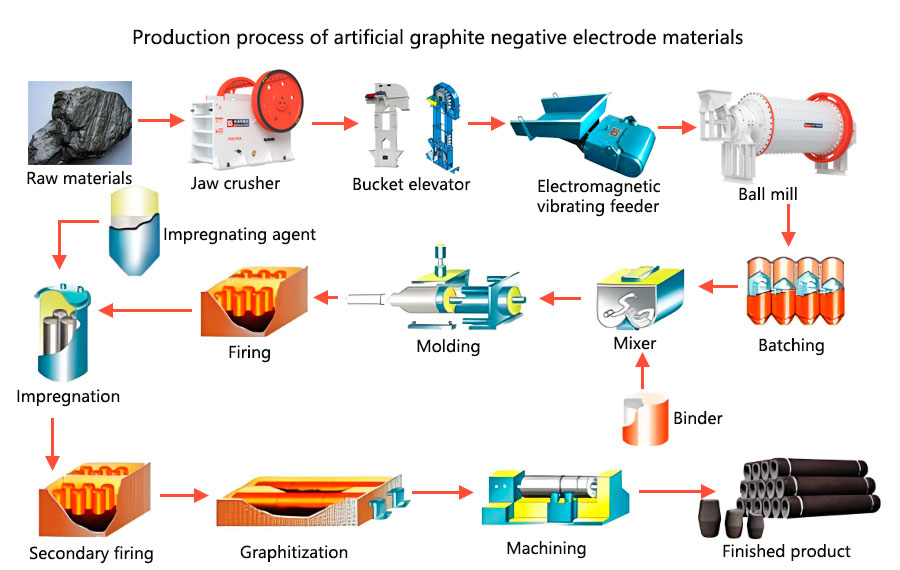

Production process of artificial graphite negative electrode material

Generally, the degree of graphitization of artificial graphite is lower than that of natural graphite. It is more stable as a lithium ion negative electrode material and can be used directly or after simple treatment. The insertion and extraction of lithium ions will not only cause a small expansion and peeling of the graphite volume, but also cause the rupture of the passivation film on the surface of the graphite, thereby consuming the electrolyte and generating a new passivation film, resulting in a decrease in reversible capacity. In order to solve the problems encountered when graphite is used as a lithium ion negative electrode material, spheroidization treatment, surface coating method, surface treatment method, doping modification method and micro-expansion treatment method are usually added to the graphite.

In short, graphite is a common natural mineral, which is widely used in batteries, coatings, pencil leads, lubrication, casting, aerospace and other fields. From daily writing tools to high-end electrical and electronic equipment, to lubrication and casting fields, and finally aerospace fields, it plays a very important role. Later, the graphite grinding process and the production process of artificial graphite negative electrode materials were introduced, which brought a lot of convenience and progress to our lives and industrial production.

What is the use of graphite? What is the grinding process?_Industral news_Xingaonai Group Report this page